What are the applications of Cable Tie?

Cable Ties (also known as zip ties or wire ties) have become indispensable across multiple industries due to their unique combination of convenience, durability, and cost-effectiveness. Below is an enhanced overview of their specialized applications and technical specifications across key sectors.

What are the cable Ties used for?

1. Electronics and Electrical Engineering Field

This domain represents the most prevalent and broad application for cable ties, and it is where the highest sales of cable ties are currently realized.

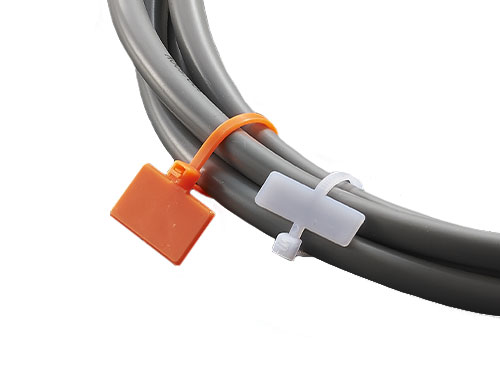

- Cable Management: They are employed to bundle wires, optical fibers, and data cables, maintaining the internal cleanliness and order of equipment such as computers, servers, and household appliances.

- Circuit Fixation: They serve to secure components or cables on printed circuit boards (PCBs) to prevent loosening.

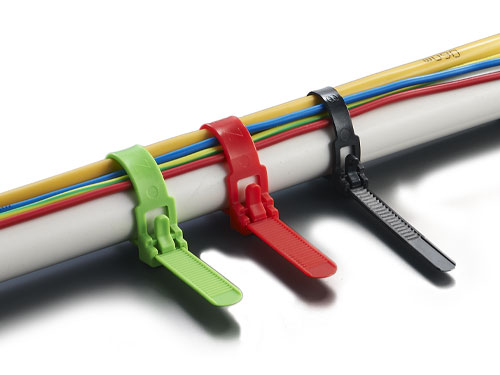

- Marking Function: Labeled marker cable ties are used for denoting routes, achieved through color coding or numbering systems.

2. Construction & Industrial Applications (Heavy-Duty Solutions)

Sales data indicates a significant use of cable ties within the construction and industrial sectors. In these industries, the quality standards for cable ties are typically stringent. It is advisable to opt for cable ties made from PA66 polymer, as substitutes made from PA6 may not suffice.

• Mechanical Fastening: Secure HVAC conduits and seismic-resistant piping systems

• Structural Reinforcement: Temporary bracing for rebar matrices and modular scaffolding

• Safety Compliance: OSHA-approved lockout ties for electrical hazard containment

3. Automotive & Transportation (High-Performance Requirements)

In the automotive industry, it is recommended to employ high-temperature resistant cable ties. Specifically, cable ties designed for automotive applications that can withstand temperatures exceeding 185 degrees Celsius are necessary to prevent breakage due to component temperature fluctuations within the vehicle.

• Vehicle Systems: Engine bay wire harnessing and fuel line routing

• Aerospace Applications: Vibration-resistant cable bundling in aircraft/spacecraft

• Rail Infrastructure: High-tensile cable tray fixation for metro systems

4. Agricultural & Horticultural (Environmental Solutions)

Recommended: UV-stabilized colored ties (minimum 5-year outdoor durability)

• Precision Agriculture: Vine training systems and hydroponic installations

• Infrastructure Maintenance: Emergency fencing repairs and irrigation line management

5. Logistics & Packaging (Rapid Growth Sector)

• Pallet Security: ISO-standard cargo stabilization for intermodal shipping

• Container Optimization: Load-lashing solutions for 40ft containers

6. Household & Consumer Goods (Child-Safe Innovations)

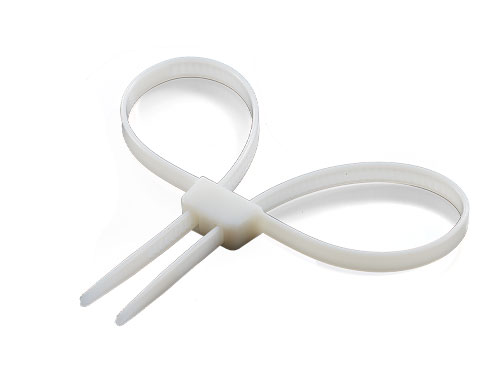

If you have children at home, we recommend releasable nylon cable ties. Nylon cable ties are made of nylon and will not cause any safety hazards even if children play with them. Recommended: Reusable nylon ties with rounded edges and food-grade materials

• Smart Home Organization: IoT device cable management

• Furniture Engineering: Non-marring temporary fasteners

7. Medical & Specialty Applications (Emerging Critical Use).jpg)

This is a neglected area, but in special times, we are surprised to find that the usage of cable ties is very large, especially the yellow environmentally friendly cable ties.

• Sterile Clinical Use: Single-use ties for surgical drape fixation

• Pharmaceutical Security: Tamper-evident packaging seals with batch tracing

8. Telecommunications & 5G Infrastructure

• Data Center Solutions: UV-resistant ties for outdoor fiber distribution

• mmWave Antenna Installation: Weatherproof tower mounting systems

9. Creative Industries & Stagecraft

• Architectural Installations: Tensile structure assembly

• Event Engineering: Rapid deployment rigging solutions

Advanced Material Selection Guide:

• Nylon 6/6: Chemical resistance (pH 3-11 range)

• 316 Stainless Steel: Marine-grade corrosion protection

• Electrostatically Dissipative: <10^4 ohms resistance

• High-Temperature Variants: Continuous 250°C service rating

Engineering Advantages Driving Adoption:

✓ 80% Faster Installation vs Traditional Fasteners

✓ 40-60% Cost Reduction vs Metal Hardware

✓ Customizable Solutions: From 2mm micro ties to 3600mm heavy-duty straps

✓ Compliance Certifications: UL, CSA, RoHS, REACH

This technical overview demonstrates how modern cable tie engineering addresses specific industry challenges while maintaining essential cost-performance ratios across applications.