Elevate Your Business with Reliable Cable Ties

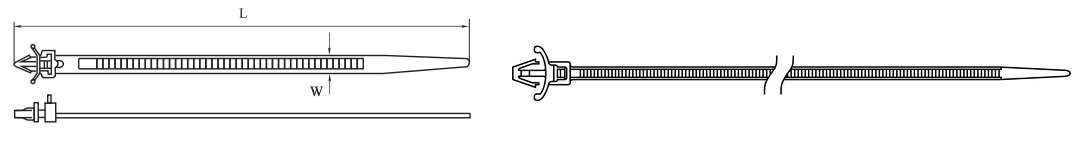

| Material: | Nylon66(UL) |

| Operatiing Temp: | -40℃ to 120℃ |

| Flammability Rating: | UL 94V-2 |

| Color: | Natural/Black |

| Application: | With a diverse range of fixing possibilities are ideal for use in many different industries, including automotive, aerospace and panel building. |

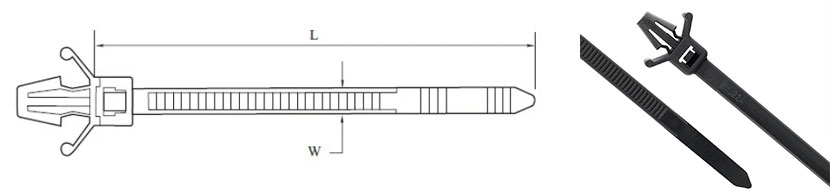

| Material: | Nylon66(UL) |

| Operatiing Temp: | -40℃ to 120℃ |

| Flammability Rating: | UL 94V-2 |

| Color: | Natural/Black |

| Application: | With a diverse range of fixing possibilities are ideal for use in many different industries, including automotive, aerospace and panel building. |

| Installation: | By hand |

| Packing: | 100 pcs bag in allsizes |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| BS-7.2x150PT | 7.2 | 150 | 6" | 35 | 6.2-9.2 | 0.3-2.2 | 62 | 28 |

| BS-8.0x220PT | 8 | 220 | 6" | 50 | 7.3-9.5 | 0.3-2.8 | 62 | 28 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength |  |

|||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |||

| BS-2.5x100PT | 2.5 | 100 | 4" | 15 | 4.2-5.1 | 0.2-2 | 18 | 8 | X01 | |

| BS-3.6x150PT | 3.6 | 150 | 6" | 22 | 4.5-6 | 0.3-3 | 40 | 18 | X03 | |

| BS-3.6x200PT | 3.6 | 200 | 8" | 35 | 4.5-6 | 0.3-3 | 40 | 18 | X04 | |

| BS-4.8x120PT | 4.8 | 120 | 4.8" | 15 | 5.8-6.8 | 0.3-3 | 50 | 22 | X05 | |

| BS-4.8x150PT | 4.8 | 150 | 6" | 22 | 5.8-6.8 | 0.3-3 | 50 | 22 | X06 | |

| BS-4.8x200PT | 4.8 | 200 | 8" | 35 | 5.8-7 | 0.3-3 | 50 | 22 | X07 | |

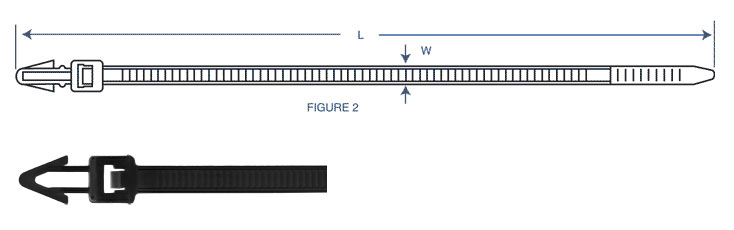

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | |||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | ||

| BS-3.6x150PTF | 3.6 | 150 | 6" | 30 | 4.4-5.3 | 0.3-2.5 | 40 | 18 | X09 |

| BS-4.8x200PTF | 4.8 | 200 | 8" | 35 | 6-7.3 | 0.3-2.5 | 50 | 22 | X10 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | |||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | ||

| BS-6x170PTS | 6 | 170 | 6.7" | 40 | 5.1-6.5 | 0.3-3 | 55 | 24 | X16 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | |||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | ||

| BS-5x120 | 5 | 120 | 4.7" | 16 | 6.6-7.3 | 0.3-3 | 50 | 22 | X40 |

| BS-5.2x165 | 5.2 | 165 | 6.5" | 22 | 7.2-8.2 | 0.3-2 | 50 | 22 | X27 |

| BS-5.2x165 | 5.2 | 165 | 6.5" | 22 | 6.3-7.0 | 2.3-3.5 | 55 | 24 | X28 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | |||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | ||

| 7.2X150 | 7.2 | 150 | 6" | 30 | 5.2-9.2 | 0.3-2.2 | 120 | 55 | X08 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 4.6x160 | 4.6 | 160 | 6.3" | 22 | 6.0-7.4 | 2-3 | 50 | 22 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 4.6x160 | 4.6 | 160 | 6.3" | 22 | 6.9-7.3 | 0.3-1.9 | 50 | 22 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 4.6x160 | 4.6 | 160 | 6.3" | 22 | 5.4-6.4 | 0.3-1.8 | 50 | 22 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 4.6x160 | 4.6 | 160 | 6.3" | 22 | 6.5-8 | 2-3 | 50 | 22 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 5.2x165 | 5.2 | 165 | 6.5" | 22 | 6.8-9.4 | 0.3-2.2 | 50 | 22 |

| Item No. | Width | Length | Max.Bundle Dia. | Hole Dia. | Panel thickness | Min.Tensile Strength | ||

| mm | mm | inch | mm | (mm) | (mm) | ibs | kgs | |

| 6.5x165 | 6.5 | 165 | 6.5" | 22 | 7.3-8.5 | 2-4 | 100 | 45 |